-

+86 18937632277

-

18937632277@163.com

18937632277@163.com

-

Lizigou Village, Lujiadian Town, Dengfeng City, Henan Province, China

Lizigou Village, Lujiadian Town, Dengfeng City, Henan Province, China -

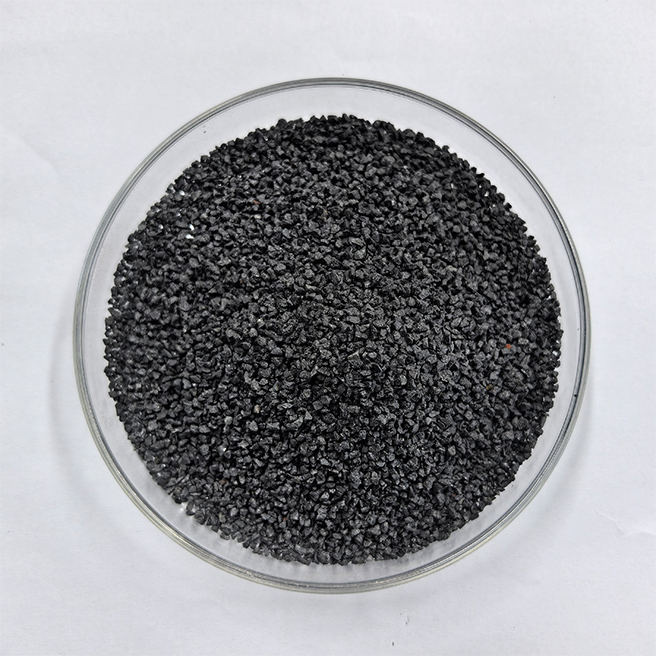

Black Fused Alumina (BFA) is an artificial abrasive produced by smelting low-grade bauxite and iron filings in a high-temperature electric arc furnace (above 2000°C). Its primary chemical composition includes aluminum oxide (Al₂O₃ 70-85%) and iron oxide (Fe₂O₃ 7-15%), with a Mohs hardness of approximately 8.5-9.0. The crystals appear black or dark gray, exhibiting high toughness, heat resistance, and excellent impact resistance. Compared to brown and white fused alumina, BFA has slightly lower hardness but offers superior wear resistance and lower cost, making it ideal for medium-to-low intensity grinding and surface treatment.

In industrial applications, BFA is widely used for:

Due to its cost-effectiveness and versatility, BFA is extensively applied in hardware processing, construction materials, automotive parts, and other industries, making it a highly economical industrial abrasive.

Key components:

| Level | Chemical Composition % | |||

| Al₂O₃ | Fe₂O₃ | SiO₂ | TiO₂ | |

| Ordinary | ≥62 | 6-12 | ≤25 | 2-4 |

| Top Quality | ≥80 | 4-8 | ≤10 | 2-4 |

Specifications:

| Color | Black |

| Crystal structure | Trigonal |

| Hardness(Mohs) | 8.0-9.0 |

| Hardness(Vickers)(kg/mm²) | 2000-2200 |

| Melting point('C) | 2050 |

| Maximum operating temperature (°C) | 1850 |

| True density (g/cm³) | ≥3.50 |

Size:

| Ordinary | Top Quality |

| Grit:F12--F400 | Grit:F46--F240 |

|

Secion sand:

3.0-5.0mm 1.0-3.0mm |

Mcropowder: F280-F1000 |

Dengfeng Bainai Abrasives & Grinding Tools Co., Ltd.

is a professional manufacturer specializing in fused alumina abrasives,

providing high-quality blasting abrasives for industrial applications.

Compared to some high-performance abrasives,

our products are offered at more competitive prices while still delivering reliable performance for routine grinding applications across various industries.

They provide excellent cost-effectiveness. Feel free to contact us anytime for inquiries!