-

+86 18937632277

-

18937632277@163.com

18937632277@163.com

-

Lizigou Village, Lujiadian Town, Dengfeng City, Henan Province, China

Lizigou Village, Lujiadian Town, Dengfeng City, Henan Province, China -

Silicon Carbide (SiC) is an artificially synthesized superhard material produced by reacting quartz sand and petroleum coke in a high-temperature resistance furnace above 2000°C. With a primary chemical composition of SiC and Mohs hardness of 9.2-9.5 (second only to diamond and cubic boron nitride), it exhibits exceptional hardness, high thermal conductivity (120-270 W/m·K), heat resistance (1600℃), and excellent chemical stability. SiC crystals are commonly found in black and green varieties, with the green type having higher purity for precision applications.

Key industrial applications include:

Due to its outstanding comprehensive properties, SiC is widely used in high-tech fields including mechanical manufacturing, aerospace, new energy, and defense industries, making it an indispensable material for modern industry.

Composition Table:

| Silicon Carbide (SiC) | 94.0 - 99.2 |

| Free Carbon (F.C) | ≤0.5 |

| Ferric Oxide (Fe₂O₃) | ≤0.7 |

| Silicon Dioxide (SiO₂) | ≤0.2 |

| Free Silicon (F.Si) | ≤0.03 |

Specifications:

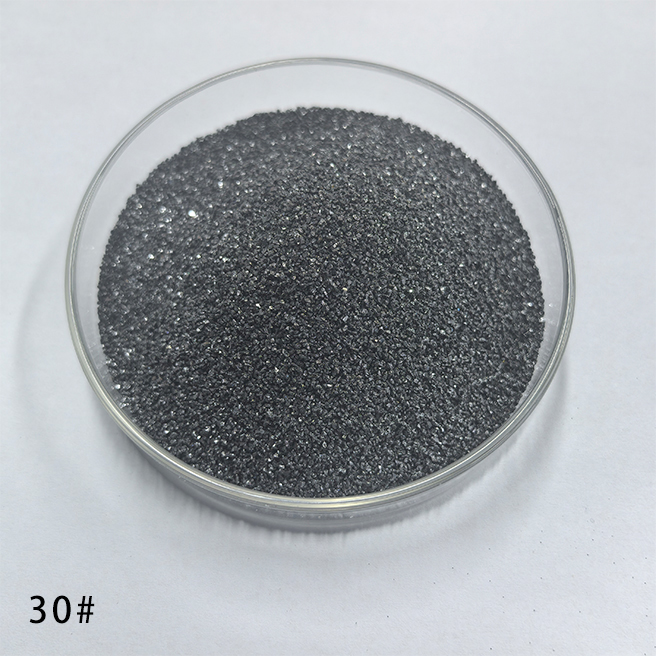

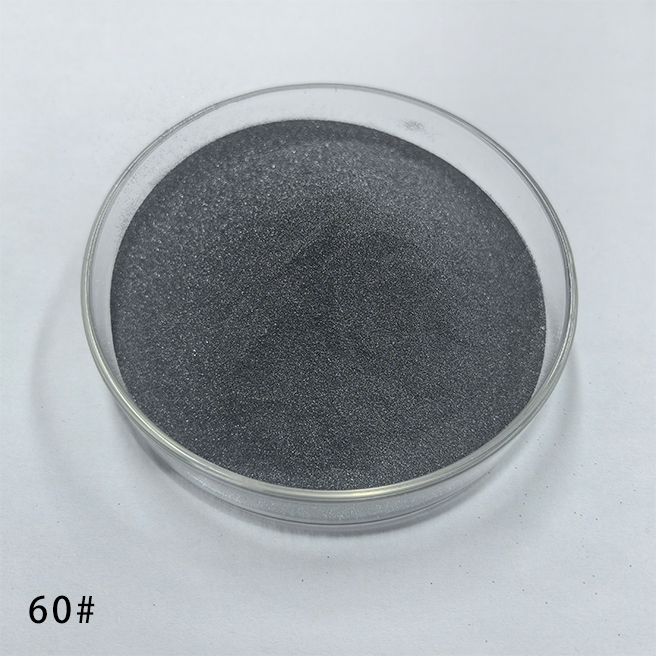

| Color | Metallic Black |

| Crystal structure | Trigonal |

| Hardness(Mohs) | 9.2 |

| Hardness(Vickers)(kg/mm²) | 2000-2200 |

| Melting point('C) | 2050 |

| Maximum operating temperature (°C) | 1850 |

| True density (g/cm³) | ≥3.25 |

Size:

| Ordinary | Top Quality |

| Grit:F12--F400 | Grit:F46--F240 |

|

Secion sand:

3.0-5.0mm 1.0-3.0mm |

Mcropowder: F280-F1000 |

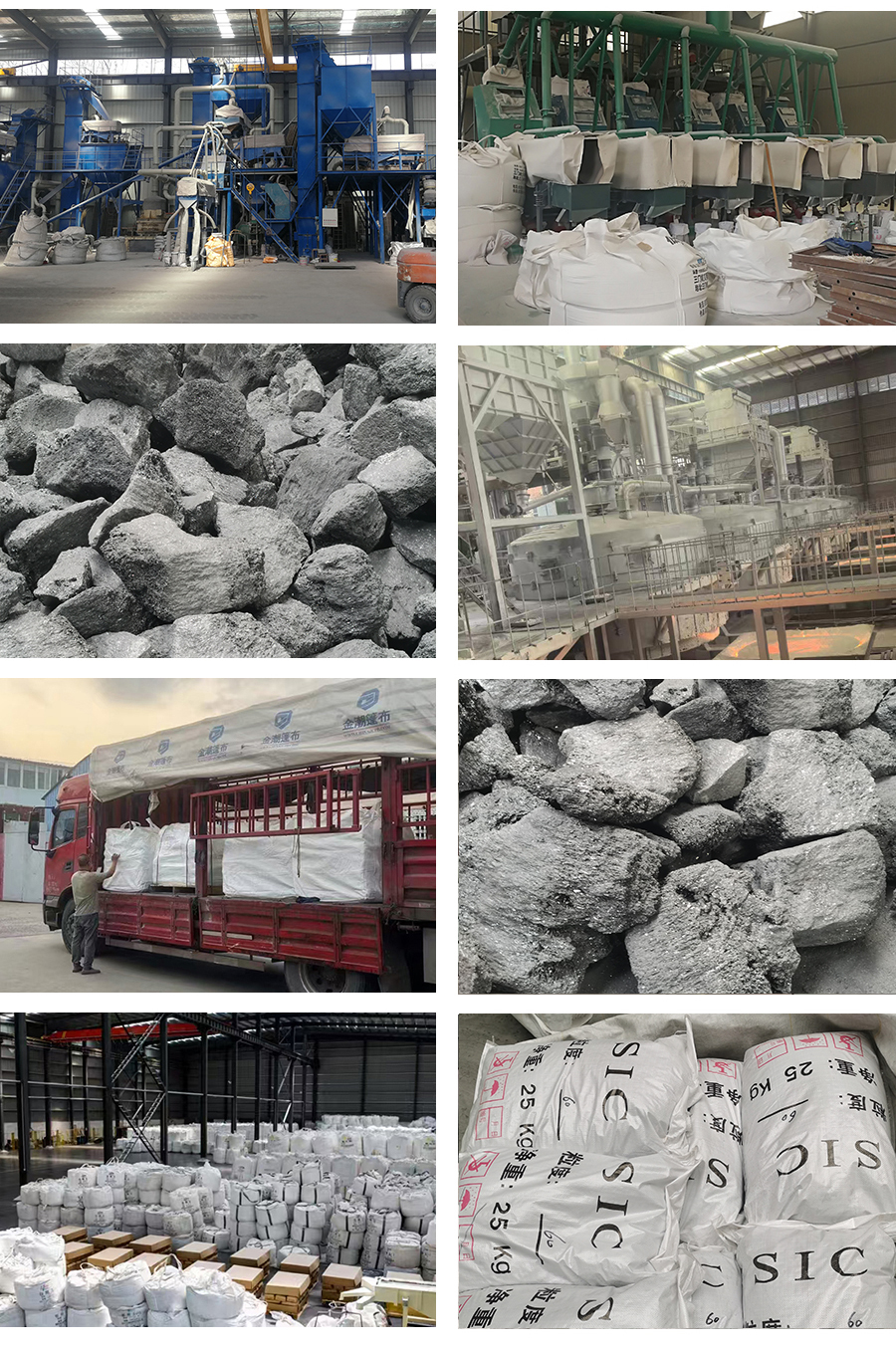

Dengfeng Bainai Abrasives & Grinding Tools Co., Ltd.

is a professional manufacturer specializing in fused alumina abrasives,

providing high-quality blasting abrasives for industrial applications.

Compared to some high-performance abrasives,

our products are offered at more competitive prices while still delivering reliable performance for routine grinding applications across various industries.

They provide excellent cost-effectiveness. Feel free to contact us anytime for inquiries!