-

+86 18937632277

-

18937632277@163.com

18937632277@163.com

-

Lizigou Village, Lujiadian Town, Dengfeng City, Henan Province, China

Lizigou Village, Lujiadian Town, Dengfeng City, Henan Province, China -

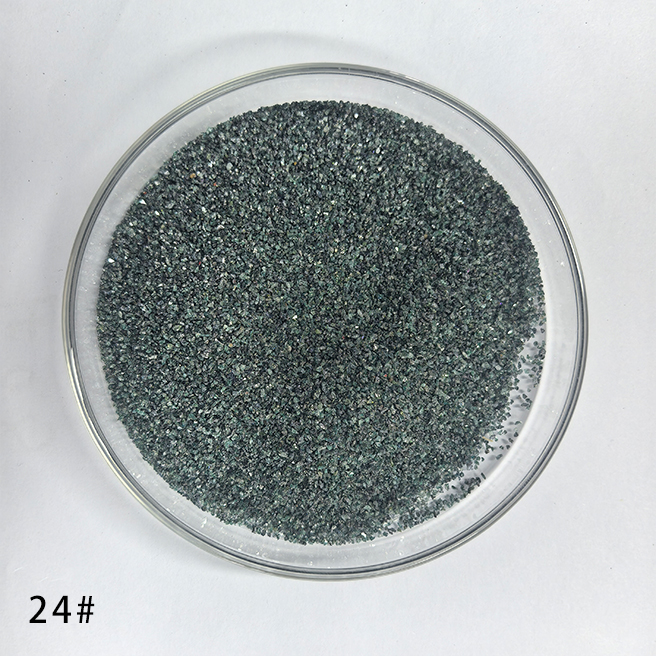

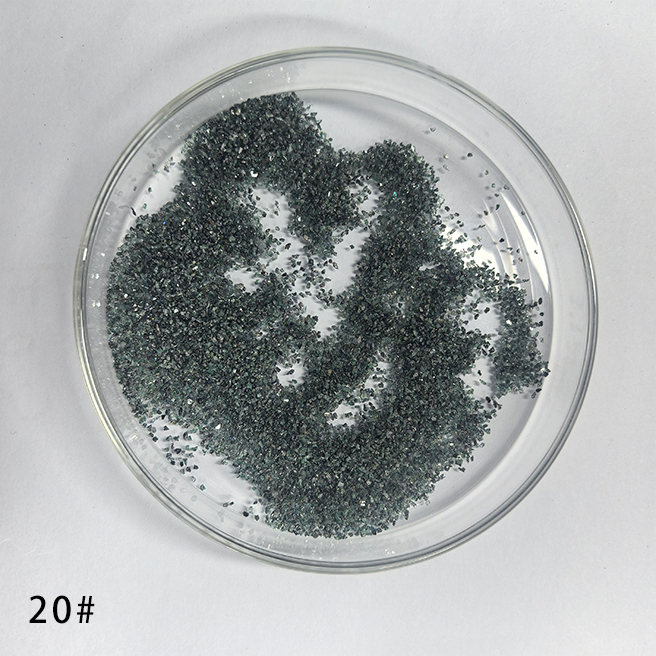

Green Silicon Carbide (GC) is a high-purity variant of silicon carbide, typically synthesized from quartz sand and petroleum coke in resistance furnaces at temperatures exceeding 2200°C. With SiC content over 99%, it features translucent green crystals, Mohs hardness of 9.2-9.5, and microhardness of 3100-3400kg/mm². GC exhibits exceptional hardness, high brittleness, superior thermal conductivity, and strong chemical inertness. Compared to black SiC, GC offers higher purity and sharper grains but slightly lower toughness, making it ideal for processing ultra-hard materials.

Key applications include:

Owing to its outstanding cutting performance and chemical stability, GC is widely used in high-tech industries like precision machinery, optoelectronics, and aerospace, serving as an indispensable abrasive for advanced manufacturing.

Composition Table:

| Silicon Carbide (SiC) | 94.0 - 99.2 |

| Free Carbon (F.C) | ≤0.5 |

| Ferric Oxide (Fe₂O₃) | ≤0.7 |

| Silicon Dioxide (SiO₂) | ≤0.2 |

| Free Silicon (F.Si) | ≤0.03 |

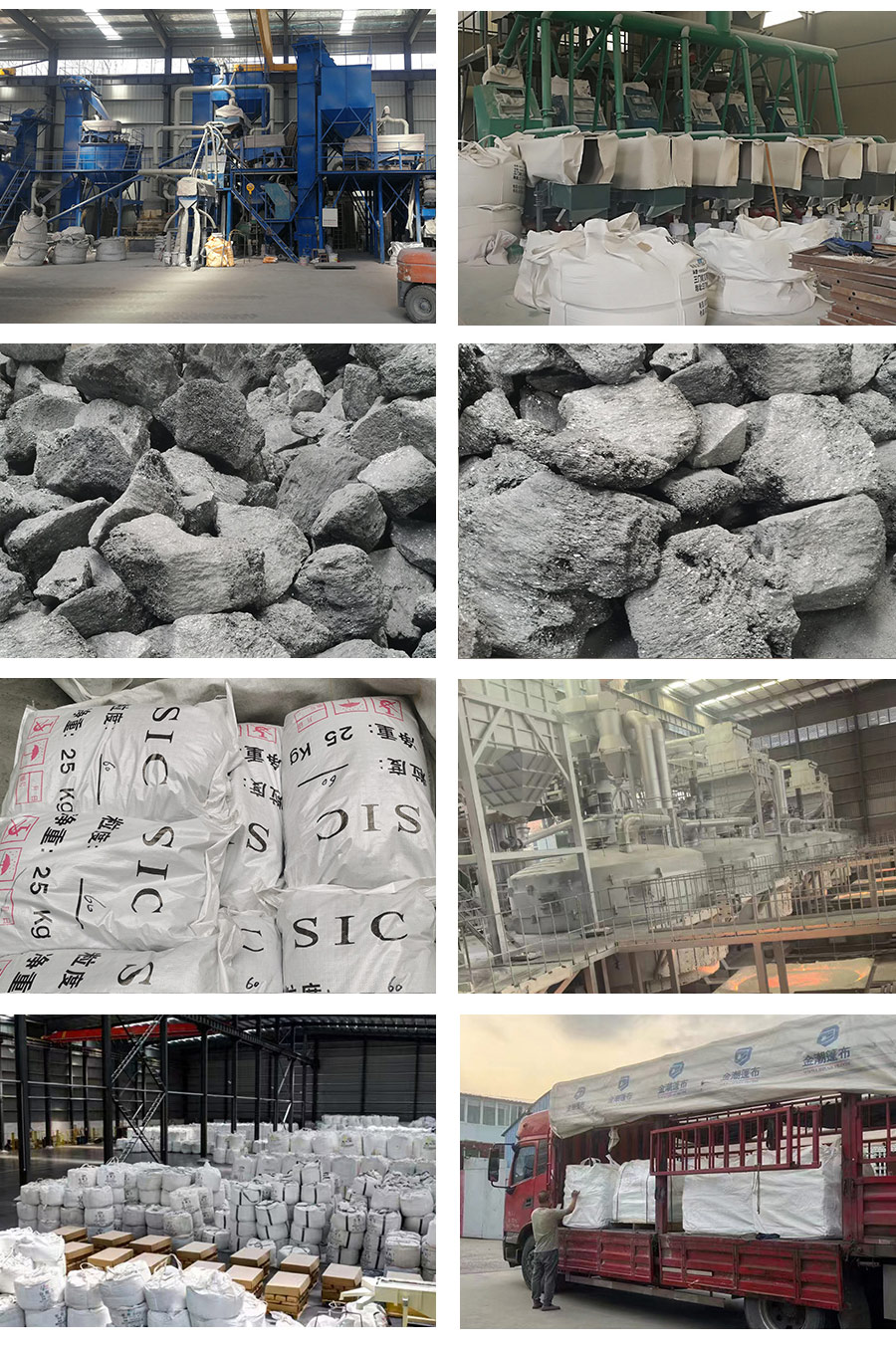

Dengfeng Bainai Abrasives & Grinding Tools Co., Ltd.

is a professional manufacturer specializing in fused alumina abrasives,

providing high-quality blasting abrasives for industrial applications.

Compared to some high-performance abrasives,

our products are offered at more competitive prices while still delivering reliable performance for routine grinding applications across various industries.

They provide excellent cost-effectiveness. Feel free to contact us anytime for inquiries!